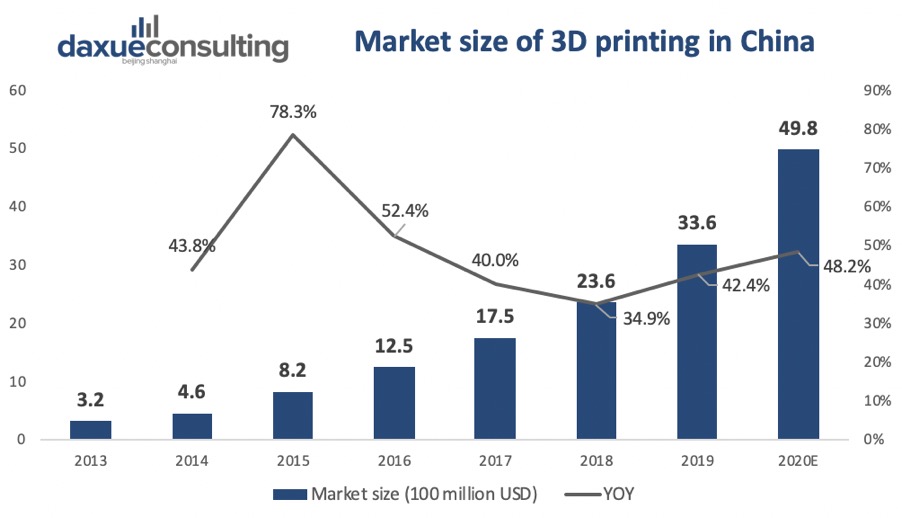

Needless to say, 3D printing in China is becoming an important industry. With the legacy of industrial manufacturing and an ambition for Made in China 2025, China is eager to claim international market in 3D printing. Domestically, the market size is rising at an annual rate around 40%, with commercial applications in home appliances, construction, orthodontics and space technologies. 80% of the total market share comes from industrial applications according to Forward Institute. In the future, 3D printing will also lend a hand to healthcare, automobile and other industries.

Source: askci research, of the 3D printing market in China

The history of 3D printing in China

As a big manufacturing country, China had embraced 3D printing with central-government-level supporting policies since 2012. In 2015, Ministry of Industry and Information Technology labeled 3D printing as one of the strategic national goals. Come 2017, the National Development and Reform Commission emphasized the industrial 3D printing, namely for large engines and space technologies. In 2018, China’s National Intellectual Property Administration listed companies in 3D printing materials as key support targets.

“The next trillion dollar industry” was the name given to 3D printing by Pascal Gobry from Business Insider. Around 2015, 3D printing in China was suggesting the creation of new opportunities in almost every industry, where with the touch of a button, actual objects can be printed out of an array of materials. Printing has now gone from spreading ink on a sheet of paper, to transforming digital files into 3D objects.

This is achieved by arranging a variety of materials including polymers, glass, metal, wax, edible food, ceramics and even human tissues into complex shapes, which would be nearly impossible to replicate by hand. Some of those objects will create the opportunity to save and extend lives or bring ease to our daily routines. 3D printing objects are achieved with successive layers of material laid down one on top of another until the desired object is accomplished. In other words, the 3D printed object is a superposition of thinly sliced horizontal cross-sections of a chosen material. The possibilities of 3D printing are breathtaking.

However, it’s not quite as easy as pressing a button. Virtual designs must be created in the form of CAD file (Computed Aided Design) supported by 3D modelling programs. Those programs offer 3D designers the opportunity to conceive objects from nothing and the imagination is free to move beyond the human handiwork. Scanners also produce CAD files, enabling existing real objects to be identically replicated in digital formats, which is often much quicker than recreating the original object.

A software must slice the digital object into horizontal layers so that the printer superposes printed slices one after the other resulting in a three dimensional object. The printing process may be performed by various technologies being improved constantly. Technologies most commonly exploited are selective laser sintering (SLS), fused deposition modelling (FDM) and stereolithography (SLA), each suggesting different advantages and responding to specific demands.

Applications & breakthroughs of 3D printing in China

The possibility of printing 3D objects will revolutionize most industries since its application is beneficial in many sectors. The application of 3D printing includes design visualization, prototyping, architecture, education, geospatial, healthcare, entertainment, retail and many more.

Food industry

Companies such as Foodini and the German Print2Taste start-up are exploiting this opportunity of creating innovating designs, shapes and decorations with printed food. The printed objects are edible by printing edible food such as icings or soft food.

Construction industry

China was noticed since 2015 by creating the “Tallest 3D-printed building” in Suzhou. The Chinese company seems to be responding to the need to build fast and efficiently. However, they’ll be facing stiff consumer hesitance as previous attempts to build quickly and efficiently had resulted in several high-profile building collapses.

Nevertheless, Ma Yihe, CEO of WinSun, is optimistic about 3D printing in China. He believes his company will build “dream factories” since the process would reduce construction materials of 30% to 60% and labor needed would be cut significantly. What’s more, It would use sand and other waste, enabling more recycling and the use of local materials. The buildings that result from 3D printing would be a lot cheaper and revolutionize the entire construction industry. Several factories were already underway in China and one is located in Dubai. However, WinSun is very controversial for patent reclamations and security concerning the stability between printed layers in the event of an earthquake.

Source: 3D printing media network, river revetment wall build in Suzhou

After years of refinement, in 2019, WinSun successfully built the world’s largest 3D-printed structure in Suzhou: a 500-meter long river revetment wall. There are many positive points about 3D-printed bricks and structures, compared to traditional material and constructions. Not only can an artificial riverbank follow the natural shapes better, it also better protects local flora and fauna. In addition, implementing and fabricating custom-designed 3D-printed bricks is way less expensive than solid walls and dams. 3D printing in China has its future, especially in construction sites where quality, precision, and speed are required.

Medical science and research

Another field that is inspiring is 3D bio printing, in the medical science world. By printing cells along a predetermined pattern, human tissues, organs, and blood vessels could be replicated. Organ printing would change the medical industry and improve life expectancy drastically. Many biotechnology firms are currently aiming at tissue-engineering applications and about to revolutionize the medical field.

In China particularly, there’s a serious shortage of organ donors. Even though the number of organ donations are on the rise since 2016, the donation per capita is only around half the world average. Anything that helps more Chinese access higher level health care would be welcomed by the medical industry. According to Yong He, professor at Zhejiang University, 3D bioprinting is valuable for pharmaceutical development and organ substitution.

However, big obstacles accompany progress, especially in the bio-medical area. Compared to natural organs, 3D-printed organs have less precision, require biological compatibility and structural strength. Those obstacles underline the multitude of bioprinting materials required to replicate a functional organ. What’s more, there’s already a strained relationship between doctors and patients. It will be difficult for surgeons to convince the population that 3D-printed alternatives are safe. Clinical trials and public education campaigns are necessary, if China wants to save more lives suffering from lack of suitable organ.

Manufacturing

Manufacturing has been improved thanks to complex 3D parts in a single build. Designing is more efficient and the experimentation phase can be completed much faster. For a long time, manufacturers have been using 3D printing to make prototypes and undertake research. If they target directly the end users, the customized products will only cost a fraction of what the traditional manufacturing does. In Hainan province of south China, a Chinese company called Sanya Suhai printed the “first 3D-printed sedan car”. The vehicle measured 3.6 meters long and 1.63 meters wide. It is powered by rechargeable batteries and reached the maximum speed of 25mph. It’s not ideal and only a work in process, but certainly a novel way to use the omnipresent lead acid batteries in China.

Education

For all those industries, art and reconstructions for education are positively impacted by 3D printing. Since 2007, 3D Print Art Shows developed to let artists express themselves in various new ways. Priceless and unique artifacts in archaeology may be reproduced for hands-on studying and research.

iDreamer 3D is another example of how China emphasizes the education of 3D technologies to teenagers. With the help of online courses, teenagers can immerse themselves with numerous 3D printing cases ranging from vehicle building to city planning. Likewise, Zhejiang Science and Technology Museum introduced China’s first 3D experience park as early as 2013.

Expand space exploration boundaries

NASA has been developing this new technology, competing to design and build a 3-D printed habitat for deep space exploration. According to Sam Ortega, Centennial Challenges program manager “The future possibilities for 3D printing are inspiring, and the technology is extremely important to deep space exploration.”

China has programs of its own too. the Chinese space program is building 3D printed space suits. 3D printing would allow astronauts to print items with a 3D printer directly in space with no freight difficulties. Those are being developed by the Shanghai Academy of Spaceflight Technology. With serious research into 3D printing in China, astronauts will be safer in their suits while spacewalking. In addition, extra suits can be constructed if they’re needed, saving time, money and resources.

New opportunities & services embraced by the Chinese government

3D printing was already getting investments from the Chinese government in the early 1990s, investments of $3.3 million were injected into in innovating institutes to promote manufacturing technologies.

As 3D printing requires mastering technologies and the capacity to create new objects relies on 3D designers, China founded the first 3D Printing College in the world, Baiyun-Winbo 3D Printing Technology College in Guangzhou in 2015. The popularisation of 3D printing means a higher demand for people producing the digital files and China is planning to respond to that need. There are also 3D printing bureaus such as Shapeways and Ponoko offering inexpensive digital designs with a relatively limited range of objects. In addition, according to Simon Shen, CEO of Kinpo Group, the Chinese government installed 3D printers in 400,000 elementary schools from 2015 to 2017. This benefits the Chinese society in the long run as teenagers are educated and skilled in 3D technology from a young age.

Source: Jiemodui, Primary school students curious about 3D printing in China.

Currently, the top-rated industrial printer is Union Tech, taking 16.4% of the 3D printer market share. Stratasys follows with 14.8%. According to Jenny Lawton, CEO of MakerBot, 3D printing will become mainstream, and certainly, 3D printing is getting implemented in China at a very fast pace. In 2014, China International 3D Printing Exhibition was held twice and recognised as one of the most valuable industry shows in the world.

Fast growth & Transformations of 3D Printing in China

The fast growth of 3D printing is partly attributed to the support of open source platforms. RepRap is a 3D printer sold for about 1,000 dollars enabling people to customize and develop open source ideas. Open-source communities such as Thingiverse and Cubify are gaining more and more interest as they provide hyper-customization and support sustainable development.

Enthusiasts for 3D printing are growing fast since 2011, thanks to its rapid development and acceptable price ($250 to $2500). People from all backgrounds are acquiring 3D printers and large-scale utilisations will increase customer options. Fabrication may become totally personalized with simple adaptation of the digital file. Thanks to 3D printing, print-on-demand and mass customization are possible. In May 2015, the highest rated desktop printer for personal printing was the Form 1+. It reached more than 400 reviews of fully satisfied customers and is considered by 3D Hubs as the most popular resin printer.

The democratization of the 3D printing technology and knowledge is expected to change the nature of commerce according to specialists. Indeed, end users will be able to manufacture their products on their own, meaning that products wouldn’t be bought from other people or corporations. Trade of the digital 3D object will however remain, so would the raw material. A long marge of progression still remains before reporting such transformations, but in our lifetime, new concepts are ready to revolutionize many industries and China making sure that it stays abreast of changes in advance, compared to foreign countries. As the president of VisenTOP, Xiao Guodong stated in 2015, “People in China are both passionate and perplexed by 3D printing technology.”