In recent years, the smart warehouse market has boomed in China. China has the largest logistics market in the world with the total market value of 252.8 trillion CNY. Warehouse management is a significant part of modern logistics industry and also the most important part of many companies’ daily operations, but most of them are still troubled by the low efficiency and high costs of traditional warehouses. Therefore, optimizing warehousing is the mission of many Chinese companies and smart warehouse has been considered the best solution.

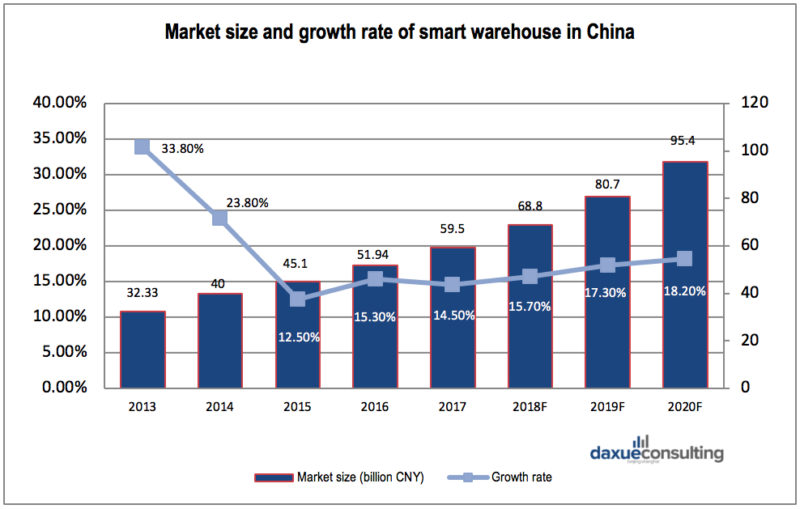

As the key part of modern logistics, smart warehouse helps enterprises automatically storage and manage goods, saving costs and improve the utilization of warehouse space. Along with the “Industry 4.0” and “Made in China 2025” launched by the Chinese government, smart warehouses have been considering as one of the most important efforts for technology implementation in Chinese logistics market. In 2016 there were about 180 main companies participating in smart warehouse market. According to the research from GGII, the market size of smart warehouses has exceeded 59 billion CNY in 2017, and it will keep the trend of increasing the in next several years. Besides, smart warehouses have been applied widely in many fields in China such as pharmaceuticals, food and drinks, cross-border e-commerce, healthcare products and etc.

Currently, automatic warehouses are the main model of smart warehouses in China. By the end of 2016, the number of automated warehouses has exceeded 3000 in China, up 19.3% compared 2015. During the same period, the total value of the automated warehouse system and relevant products has exceeded 39 billion CNY in China with 20% year-on-year growth. According to the “Forward the Economist” (前瞻经济学人), in the next 5 years, it will exceed 110 billion CNY with 10%-18% growth speed.

The e-commerce and delivery industries are promoting the development of smart warehouse

Costs and efficiency are the main issues of warehousing aspects for e-commerce and delivery companies and smart warehouse is the best solution for them.

- High costs of traditional warehousing

Since the rapid development of e-commerce industry, China’s logistics has been facing high costs for years and the costs of warehousing occupied a large account of them. By the end of 2017, the total costs of logistics have reached 12.1 trillion CNY in China, up 9.2% compared with 2016. Among all costs, storage fee has reached 3.9 trillion CNY, up 6.7% compared 2016. In the meantime, management costs have reached 1.6 trillion CNY, up 8.3%. The costs of warehousing mainly consist of storage and management expenses, thus, the share of warehousing costs have exceeded 40% among total logistics costs in 2017 in China. Besides, traditional warehouses normally cover a wide area, their high land costs is another issue.

For delivery companies, its boom is closely related to the growth of e-commerce in China. Based on the data from the National Bureau of Statistics, in 2017, the number of finished parcel deliveries has exceeded 40 billion, and there were 70% of them created by e-commerce. The most experienced part of delivery companies is sorting in warehouses, which takes 40% of their total costs. Especially for large delivery companies, they have to hire a large number of experienced employees to deal with the increasing number of parcels.

- Low efficiency of traditional warehousing

Due to online shopping is extremely popular among Chinese people, the demand for warehousing is getting higher and higher. During the well-known event “Double 11” (双11) in 2017, the number of delivery orders exceeded 657 million. But, traditional warehouse relies on a lot of experienced employees who are hard to hire and could cause the wasting of human resources. Also, it is hard for the traditional warehouse to avoid errors during the peak period of logistics.

In order to decrease the costs and improve efficiency, e-commerce and delivery companies have started to build smart warehouses since they have obvious advantages to achieve the targets. For instance, in September 2017, “JD” (京东商城) firstly introduced its smart warehouse system, the unmanned warehouse “No1. Asia” (亚洲一号). According to the data from JD, the storage efficiency of the unmanned warehouse is 5 times of traditional warehouse and it can make full use of warehouse space with a way of high-density storage. In the sorting step, the sorting machines in unmanned warehouses have capable of sorting 40 thousand goods per hour with the accuracy of 99.99%, which has exceeded 10 times of manual sorting in traditional warehouses. By building and using unmanned warehouses with the highly automated system, JD succeeded in reducing labour costs and effectively relieves the stress from popular shopping events in China, such as Double 11 and 618.

Except for JD, other e-commerce and delivery companies like Alibaba, ShenTong (申通快递) and Shunfen (顺丰快递) also joined the smart warehouse market. Also in September 2017, “Cainiao” (菜鸟网络), the largest logistics platform under Alibaba Group, started to launch smart warehouse system with a group of robots in China. In 2016, ShenTong, the well-known delivery company in China, has started to use automated sorting robots in their warehouses.

High-tech automatic equipment is essential for smart warehouses in China

Smart warehouses are the representative of automation and robot usage in Chinese logistics market. The key part of a smart warehouse is to replace people with highly automated machines. By using automatic robots, a smart warehouse can save around 70% labour costs. Nowadays it is not difficult to produce and purchase automatic robots benefited from the development of the automation industry in China, and the one mostly used by smart warehouses is an automated guided vehicle (AGV). Based on the different purposes in smart warehouses, AGV can be divided into 4 major kinds.

- Picking robots

Picking robots are used to move goods shelves to certain administrators and areas based on the orders they received.

- Sorting robots

After receiving orders, by scanning a barcode, sorting robots will automatically choose routes and move different kinds of products to their own processing areas.

- Handling robots

By using vision-based navigation technology, this kind of robot can auto-complete any transforming task between any two points in the smart warehouse

- Palletizing robots

Palletizing robots are mainly presented as robot arms, they can be used to automatically stack and pack goods in a smart warehouse.

This kind of emerging sector (unmanned warehouses, but also unmanned stores for instance) is also a support for the development of high-end tech in China, where the objective is clearly to lead the worldwide market: facial recognition, AI, automated robot, drones, data processing etc. —— Thibaud Andre, Daxue consulting

Automatic technologies also bring costs and challenges to smart warehouses in China

For building a smart warehouse, the main costs and challenges also come from automated machines and technologies behind them. According to the data from some providers and e-commerce platforms such as Taobao, unite price range of palletizing robot is between 20 thousand CNY to 100 thousand CNY. The average unit price of sorting robot is around 150 thousand CNY. However, the prices are only for reference, the actual price is closely connected with the functions, quality and quantity of those automatic robots. Moreover, in order to build a smart warehouse, hundreds of automatic robots are necessary. Thus, the costs of building a highly automatic system are hard afforded by small companies.

Due to the purpose of smart warehouses is to replace human staff by automatic machines, the most important parts are controlled and organize hundreds of robots to build a highly efficient group and deal with a large number of packages. As we know, the technologies used in smart warehouses mainly consist of automatic control technology, intelligent robot technology, intelligent information management technology, mobile computing technology, data mining technology etc. But, many manufacturers and providers still have to import some core technologies such as automatic control technology and mobile computing technology. In some circumstances, part of companies even needs purchase hardware from overseas such as highly automatic sensors on robots. In addition, the key problem for palletizing robot is the control system, the control system used by domestic companies has obvious disadvantages on control precision and quick response. For solving those issues in smart warehouses, domestic companies have to focus on R&D and importing with high costs.

Industrial and intelligent robots manufacturers will benefit from the development of smart warehouse in China

China has been the world largest robots consumption market as early as 2013, but domestic manufacturers only owned 30% market shares and most of them only confined to low-end products. Along with the rising of smart warehouse market, the demand for industrial and intelligent robots has been growing for years in China. More and more capable e-commerce and delivery companies will start to build smart warehouses to improve their efficiency of logistics, thus, domestic providers and manufacturers will achieve great benefits from smart warehouse market if they can develop products with more advanced technologies.

China Paradigm Episode #6: How to get China’s largest companies behind your tech startup

For deeper insight into China’s smart warehousing, see the China Paradigm podcast interview with Shuyang Cao, one of China’s leading experts and entrepreneurs on smart warehousing robotics. Shuyang is the co-founder of Malu Innovation, a company that is revolutionizing warehousing in China and the rest of the World. This interview covers starting a warehouse robotics company from scratch, the journey of building the robots, and how the founders convinced JD.com to invest in their business.

China Paradigm is brought to you by Daxue Consulting

Daxue Consulting can provide strategic positioning for international brands aiming to integrate into Chinese smart ecosystems

Daxue Consulting has developed an extensive experience and network among the Chinese smart city ecosystems and related industries, including projects in data processing systems, connectivity offer monetization, and smart lighting and urbanization models. Our team can answer your need for information and leverage our knowledge of the market to provide key strategic insights on your implementation in China. Contact us for more information and set up a call with one of our senior research directors.