Original Equipment Manufacturer (OEM) companies are conventionally described as firms that produce products that would then be used as components by another firm, commonly referred to as Value-Added Reseller (VAR), to produce the finished product for customers.

China is one of the most popular destinations to choose an OEM. The country has earned the “World’s Factory” moniker due to its robust economic environment, low labor costs, lax enforcement of labor laws, low taxes and customs, and competitive currency practices. With numerous choices available, understanding Chinese OEM companies and their competitive advantage are vital.

What is an Original Equipment Manufacturer?

Original equipment manufacturers (OEMs) and value-added resellers (VARs) work together. OEMs create subassembly components to market to VARs. Some OEMs do produce finished goods for a VAR to sell. However, they often have little direct control over the final product. Therefore, OEMs usually concentrate on B2B sales while VARs on end-users.

An OEM differs from a third-party manufacturer, which creates components for the aftermarket –equipment created by another business that customers can use in place of the original. An original equipment manufacturer’s products are made especially for the original product.

An OEM firm is also different from an original design manufacturing (ODM) firm. ODM is a private labelling method for manufactured products. Although an ODM company can build and manufacture a product in accordance with its own needs, it can also change the design to fulfil the demands of a client company. The client may then sell these goods under their own brand.

Original equipment manufacturers are especially common in the automotive and IT industries. Despite being usually referred to as a company that delivers a single product part to another company, an OEM in the computer software and hardware industry could also mean a company that buys another company’s product and repackages it as its own. For instance, Microsoft provides software to companies such as Hewlett-Packard (HP). If we are following the conventional definition, in this case, Microsoft is the OEM while HP is the VAR. However, many in the computer industry would say otherwise. Thus, it is important to understand what type of OEM is discussed.

The benefits and drawbacks of partnering with an OEM company

By working with an OEM, a firm would be able to reduce manufacturing investment, production and material costs. Thus, the said firm then focuses on acquiring product design expertise and a shorter product life cycle. However, partnering with OEM also has an implication for the product development cycle.

Benefits

- OEM customers preserve full creative control over their design.

- There are also little to no intellectual property constraints, allowing OEM customers to change to other manufacturers in the future, if necessary.

- Flexibility in the product design, allowing customization for OEM customers.

Drawbacks

- OEM companies are only going to produce the products based on the design sent by their clients. Therefore, there is no troubleshooting done from the OEM side even if there is something wrong with the product design.

- OEM clients would have to pour in a high level of resources in order to create a unique product. The resources include R&D cost, product testing, and marketing and sales. This can mean that there is a longer development cycle when making a product.

China’s original equipment manufacturer industry

According to Interact Analysis’ research, total global manufacturing industry output is estimated to have a 4% growth in 2022, reaching a value of US$44.5 trillion. However, a dip of US$200 billion in 2023 is predicted, followed by a rebound in 2024 and 2025.

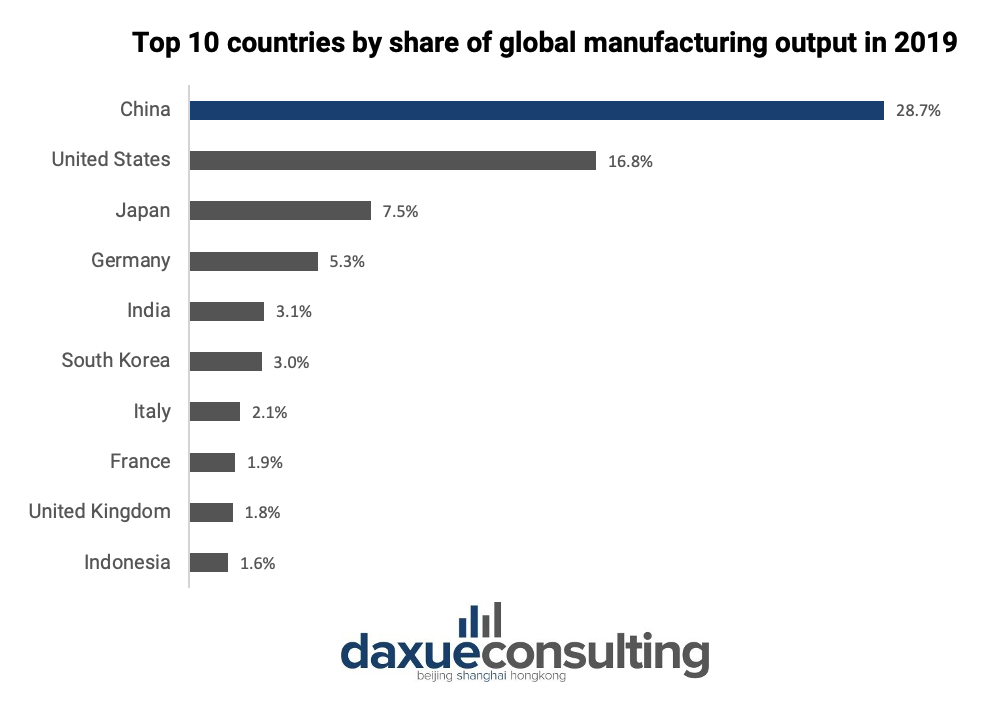

In terms of manufacturing output, China is a manufacturing superpower, leading the global race in 2019, producing 28.7% of the world’s manufacturing output. This means that China’s manufacturing industry contributed roughly US$4 trillion to the nation’s overall economic output.

Western firms have depended on China’s manufacturing industry in order to produce their goods at low cost and export them back to the markets where they may be sold with a high margin of profit. Though, the situation has shifted recently.

The impact of COVID-19 and lockdowns on the manufacturing industry in China

Today, China has hundreds of millions of consumers who fly overseas or purchase foreign goods online, while low-cost manufacturing is being displaced by high-tech firms. OEM manufacturing has lost some of its former leverage on governmental regulations in this changing socioeconomic environment. China’s economy is currently expected to become even more integrated into the global capital system with the “Belt & Road Initiative” and the “Made in China 2025” plan.

According to Bloomberg, nearly one in four European firms are thinking of moving production from China to other countries with ASEAN as a popular destination due to COVID outbreaks and lockdowns. However, the businesses that are considering shifting out of China are mainly in the industries that offer low added-value such as textiles and clothing, and electronic packaging and testing. This is partly a result of the Chinese workforce’s upskilling and rising expectations regarding the nature of jobs and salaries.

The entire manufacturing industry is still heavily reliant on the Chinese industrial supply chain despite the relocation of some processes from China. Due to their reliance on these established supply chains, more complex industries like automotive, high-end electronics, and semiconductors are more challenging to outsource on a wide scale. Thus, China’s manufacturing industry has nothing to worry about, at least in the short to medium term, as it still plays an important role on the global scale. However, the production of automobiles, electronic components, and semiconductors is located in places that have been severely affected by recent pandemic waves, such as Shanghai, Shenzhen, and Jilin. As a result, their productivity has been particularly negatively impacted.

Chinese OEM companies in the electronics sector

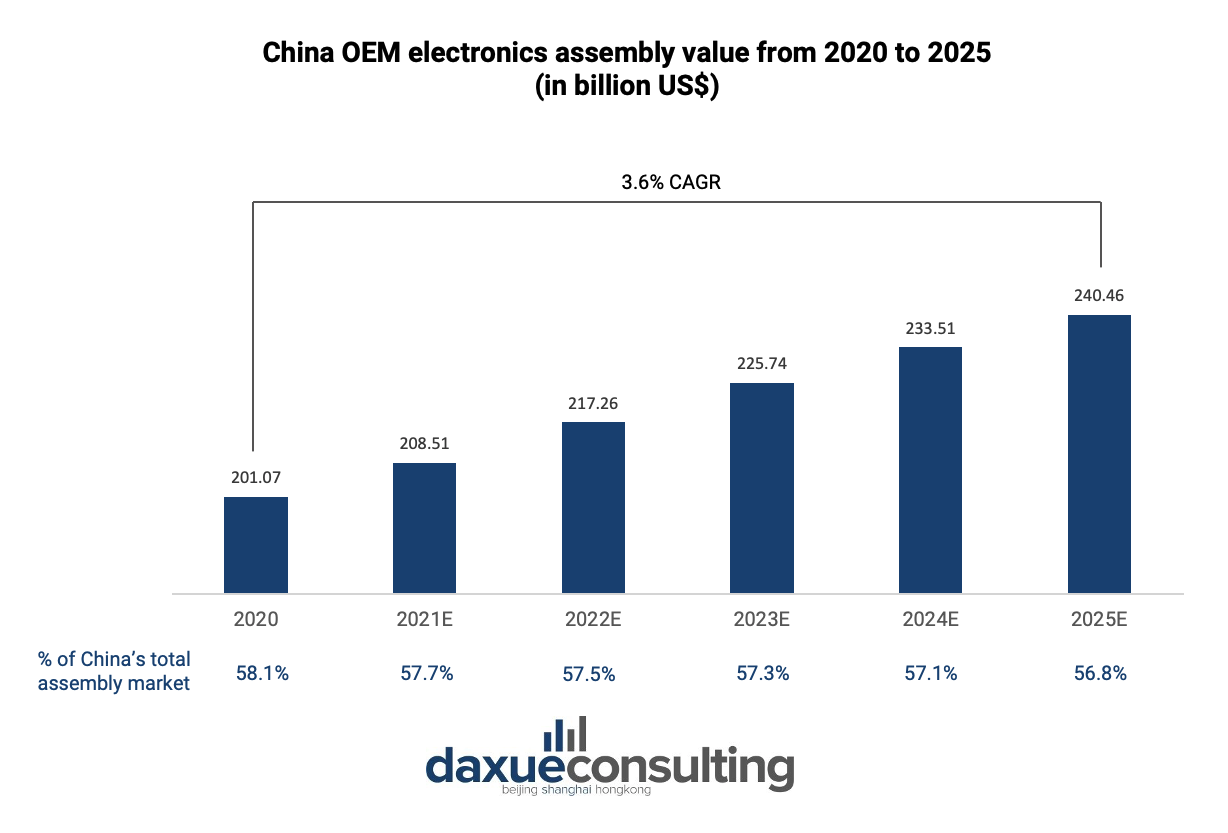

Even with the pandemic, the value of China’s electronic assembly industry reached a record high of over US$346.3 billion in 2020, accounting for almost half of the Asia Pacific market. Its OEM assembly value accounted for 58.1% of the nation’s total electronics assembly value, generating around US$201.1 billion.

In 2020, Chinese OEM companies dominate the top 10 electronics OEM suppliers in China. However, there are several foreign firms on the leaderboard. As a whole, the top 10 companies take 52.8% of the total market share in China.

Things to consider when choosing Chinese OEM companies

After shortlisting several companies, the next step is to consider the essential details of those OEMs which include certifications, business licenses, experience in exporting products to the desired countries, and minimum order quantity (MOQ).

Hiring a sourcing agent can also yield several advantages as they can discover and verify various manufacturers on your behalf. These sourcing agents possess broad partner networks and an in-depth understanding of the sourcing industry. The sourcing agent can also visit the manufacturers to see the factory in person and have meetings with key staff members.

When it comes to choosing Chinese OEM companies, there are also a couple of other important factors to consider such as trade infringement and the OEM firm’s corporate social responsibility (CSR).

Trade infringement

As mentioned beforehand, the Chinese government launched the “Made in China 2025” program which showcases a fresh, ambitious plan to promote Chinese companies and industries abroad and transform the country from a global “factory” into one that generates higher-value goods and services. The program’s shift in policy is also evident in recent legal developments pertaining to the connection between OEM manufacturing and trademark infringement.

Corporate Social Responsibility

After finding a trustworthy original equipment manufacturer, the employing company must certify that the OEM company’s ethics and vision are compatible with its own. Compared to the US and EU, Chinese labor laws are less strict. As a result, workers work longer for very little salary. For example, workers working in a Chinese factory for Hasbro, Mattel, and Disney were found to be mistreated in the run-up to Christmas.

The employing company should accept responsibility and refrain from signing contracts with such OEMs as it is unfair and unethical. There have been several instances where firms have chosen to sign agreements with unethical OEM companies, which can have extremely detrimental effects on the brand.

What to know about Chinese OEM companies:

- The term “original equipment manufacturer” (OEM) refers to businesses that produce goods which are later used as components by another business. It is commonly observed in the automotive and electronic industries.

- OEM is different from a third-party manufacturer and an original design manufacturer (ODM).

- Working with an OEM firm allows a company to focus on attaining product design expertise, yet it also means that the hiring company would have to spend more time and money on developing the product.

- China’s manufacturing industry is ranked first in the world based on manufacturing output and the country is labeled as the “World’s factory”.

- There has been a change of landscape in China’s manufacturing industry in recent years due to COVID-19 and frequent lockdowns.

- European firms are moving their production site outside of China. However, China’s manufacturing industry will continue to play an important role in complex industries such as automotive, high-end electronics, and semiconductors.

- Local trade infringement and CSR are some of the other factors that must be examined before deciding whether relying on an OEM company in China.

Author: Regina Sukwanto